Select Machining Technologies

Select Machining Technologies brings globally recognized brands of CNC machine tools designed and engineered for machining large, complex components, typically 30" cube and larger to manufacturers throughout the USA. We distribute this technology through industry-leading full-service distributors; Morris, Hartwig, Gosiger, and Arizona CNC. By combining advanced manufacturing technology with support from the industry's most knowledgeable distribution channel, we deliver solutions to Your BIGGEST machining challenges.

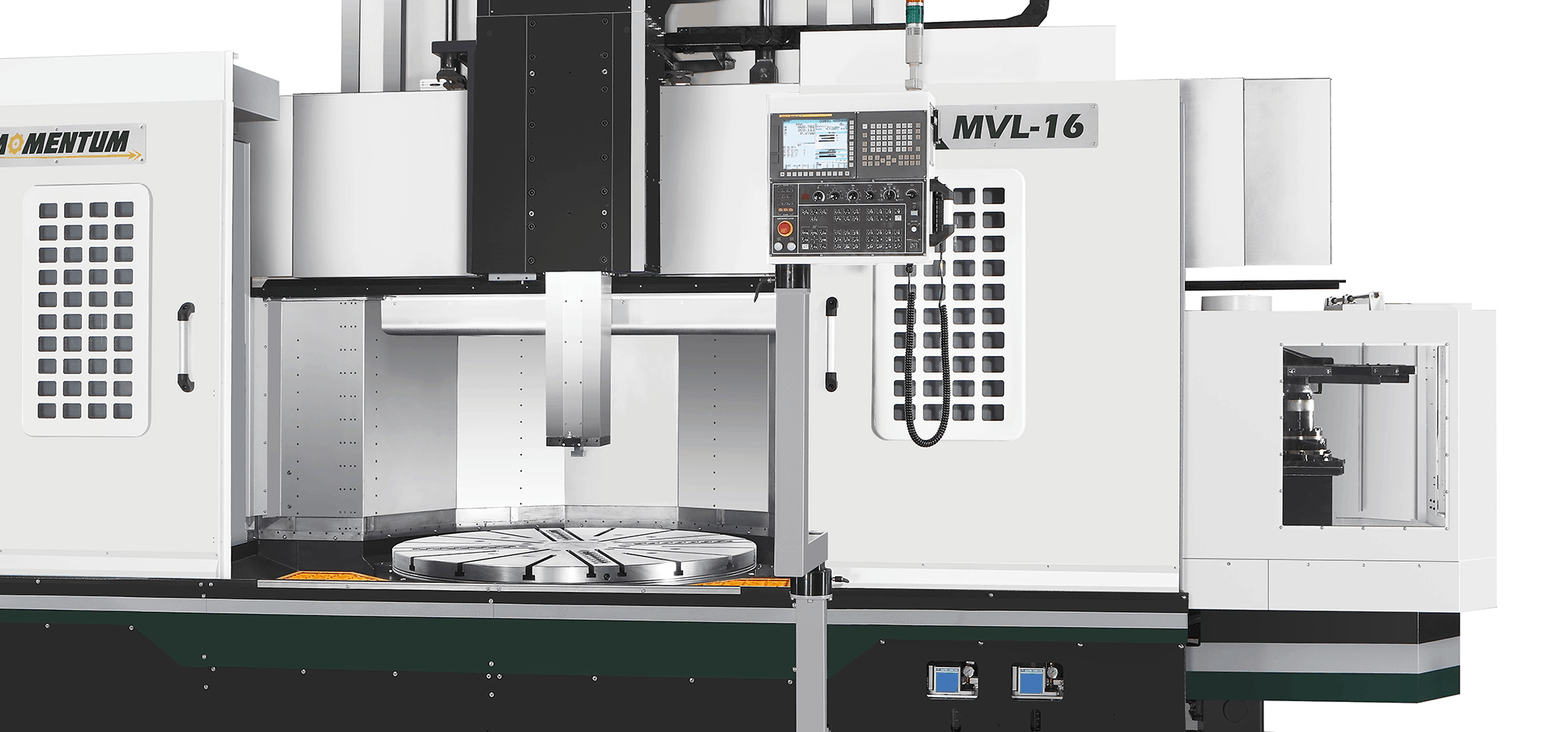

Stronger, Faster and more Efficient, ZVH Moving Column Machining Centers

The most powerful machine of its kind, the 6th generation IBARMIA Z Series moving column multitasking machining center is now Stronger, Faster and more Efficient for an even bigger ROI.

• 30% faster acceleration on the traveling column reducing cycle times

• 10% faster tool changes reducing cycle times on complex parts

• 20% increased workspace for machining larger components

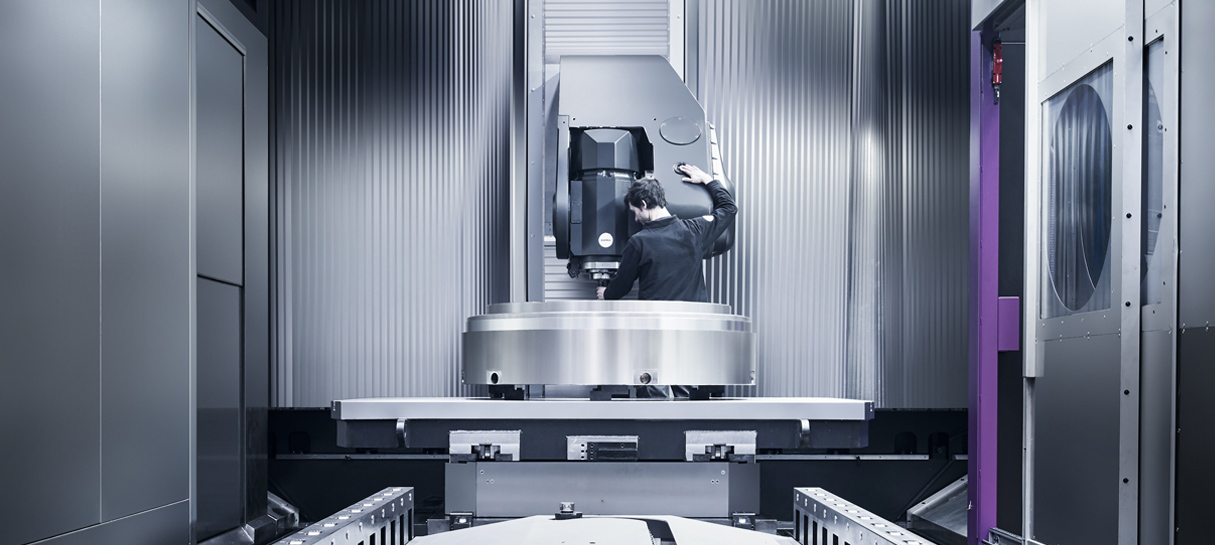

Milling, Threading, Turning and Grinding Components Complete on a SORALUCE

Coffin Turbo Pump has realized a 35% to 40% reduction in machining time by CNC milling, threading, turning and grinding in their new SORALUCE TAM 25 multitasking machining center. The SORALUCE machining center is the single largest investment made in their plant in over 20 years.

“It’s a game changer” - Jim Kinneary, President and CEO

Introducing the GEMINIS GM9i Multi-Process Turning Center

In this machine walkaround video, Doug Schulte, aka the Machine Tool Google, goes over the features of a Geminis GM9i Multi-Process Turning Center on the factory floor in Spain, before being shipped to a US based steel mill. Doug shares many of the design features that were developed specifically for the machinist, to provide easy, safe access to oversized parts being machined.

FIBA Industries Boosts Productivity with Soraluce Multitasking Machine

Enjoy this interview with Matt Sprogna, Director of Operations at FIBA Industries in Littleton, MA to learn how they've increased productivity on large storage vessels / tanks with the recent addition of a Soraluce FLP 14000 floor-type milling, boring, multitasking machining center